IOCB Prague unveils a fundamentally faster, more affordable way to produce quantum-grade nanodiamonds

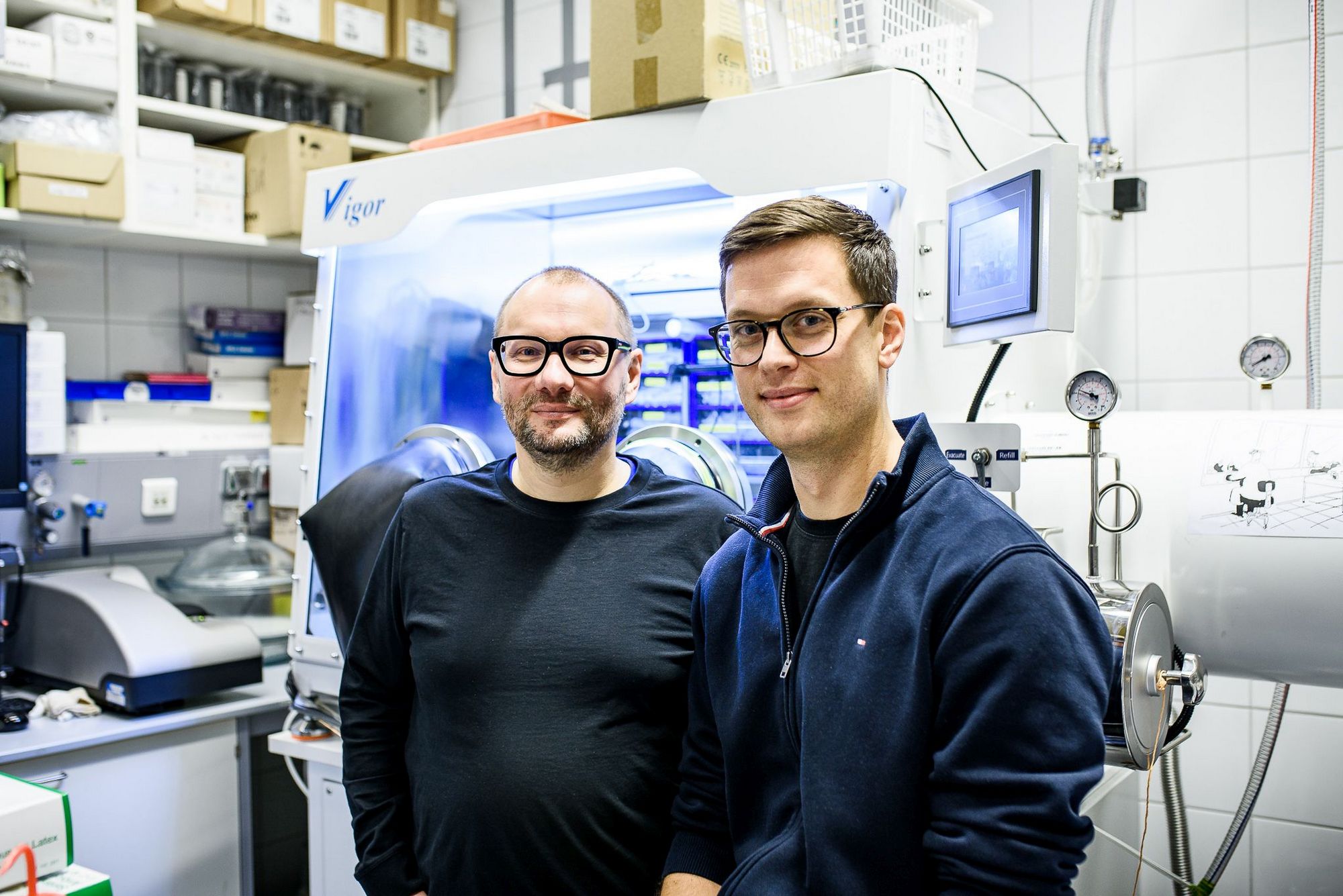

An international team of scientists from three continents led by Dr. Petr Cígler of IOCB Prague has developed a method for creating light-emitting quantum centers in nanodiamonds in only a matter of minutes. In just one week, the process can yield as much material as conventional methods would produce in more than forty years. Moreover, the resulting nanodiamonds show improved optical and quantum properties. The breakthrough brings us one step closer to the industrial production of higher-quality and more affordable quantum nanodiamonds, which have broad applications in research and technology. The article was published in the scientific journal Advanced Functional Materials.

The breakthrough marks a major step toward advanced technologies in medicine and industry

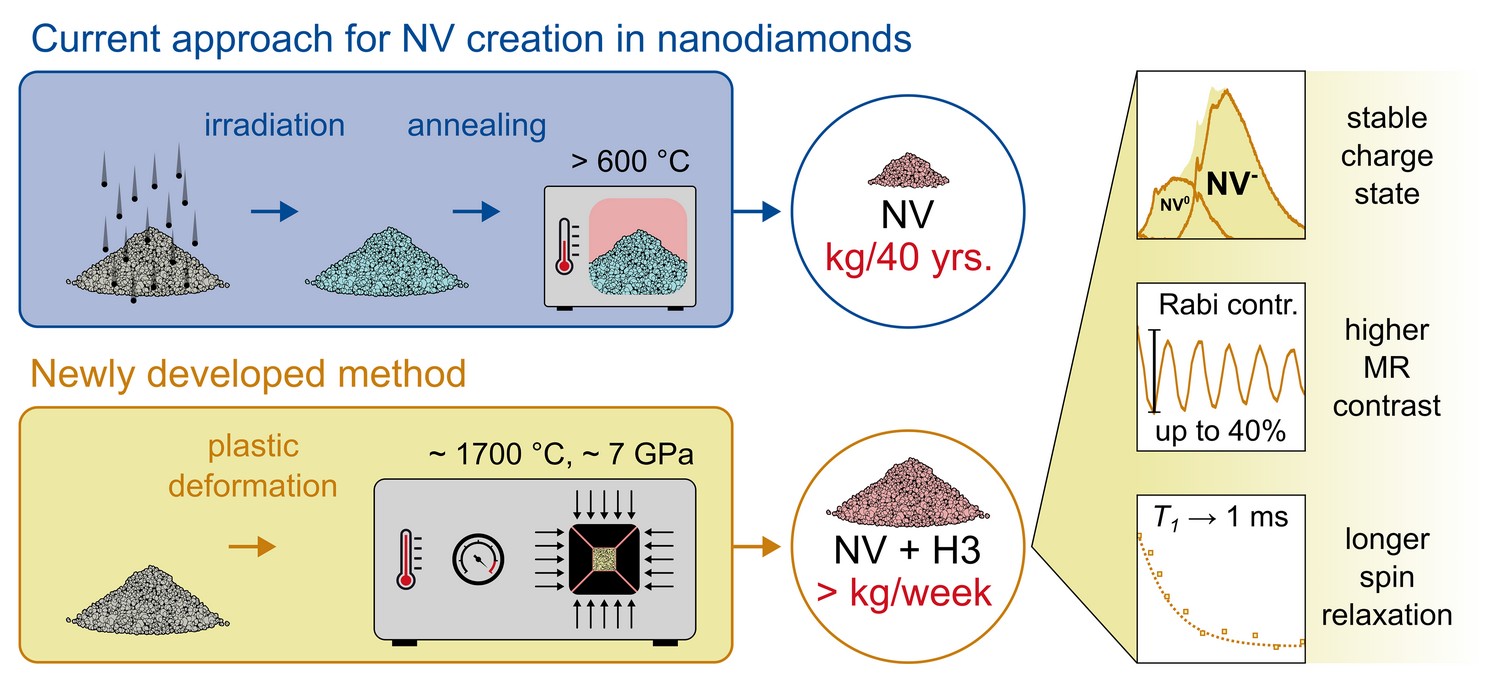

The research team has introduced a new procedure called Pressure and Temperature Qubits (PTQ), which takes only four minutes. Diamond powder is placed in a press that generates extremely high pressure and temperature, reproducing the conditions found deep within the Earth’s mantle. Under these conditions, quantum centers are formed inside the nanodiamonds. To prevent the particles from fusing together, ordinary table salt is added. It melts during heating, creating a protective environment. After the process, the salt is simply removed with water, leaving a pure, luminescent material.

“We’ve accelerated the creation of quantum centers in nanodiamonds more than a thousandfold compared with the standard procedure. Until now, diamond powder had to be irradiated with a beam of charged particles for two weeks and then annealed at high temperature. The result was less than a gram of usable material. We can now produce it in kilograms,” says Dr. Michal Gulka, a postdoctoral researcher in Petr Cígler’s group and first author of the study.

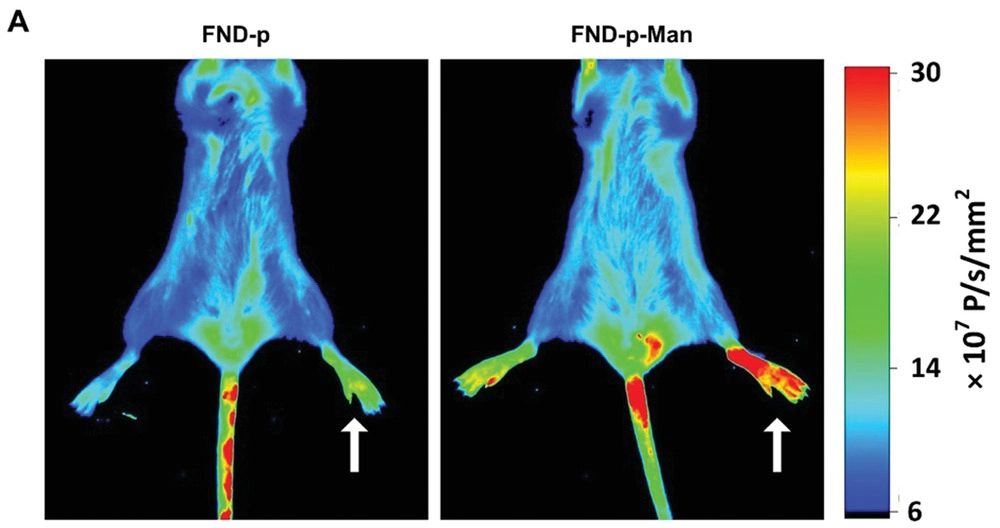

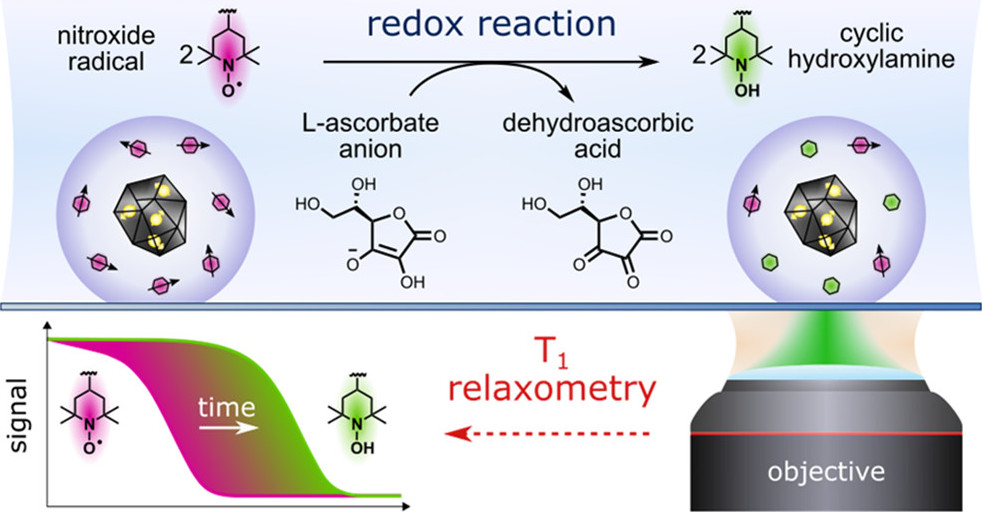

Nanodiamonds are particles smaller than a virus that are used in advanced diagnostics to measure magnetic fields, charge, or temperature. They function as highly sensitive sensors thanks to a nitrogen-vacancy (NV) center – a nitrogen atom located next to a missing carbon atom in the diamond lattice. The NV center is fluorescent, meaning that when illuminated, it emits light. The intensity and timing of this light depend on changes in the surrounding environment, allowing nanodiamonds to detect even individual molecules or measure temperature inside cells.

A key contributor to the project is the American company MegaDiamond, which plans to launch industrial production of these nanosensors.

“Thanks to the new method, laboratories and companies around the world can obtain large quantities of high-quality nanodiamonds with NV centers, which opens the door to new technologies – from precision sensors for medical diagnostics to local molecular detectors based on principles such as magnetic resonance,” adds Dr. Petr Cígler.

The study was supported in part by the AMULET project, which focuses on developing multiscale nanomaterials and brings together eight partners led by the J. Heyrovský Institute of Physical Chemistry. Funding was provided through the Jan Amos Komenský Operational Programme of the Czech Ministry of Education, Youth and Sports, under the Excellent Research category.

Original article

- Bao, Y.; Gulka, M.; Kumar, P.; Copak, J.; Balasubramanian, P.; Mindarava, Y.; Blinder, R.; Olney‐Fraser, M.; Wen, H.; Spanielova, H.; Zeng, H. Z. J.; Whitefield, B.; Aharonovich, I.; Hruby, J.; Jelezko, F.; Belnap, J. D.; Chang, S. L. Y.; Cigler, P. Quantum‐Grade Nanodiamonds from a Single‐Step, Industrial‐Scale Pressure and Temperature Process. Adv. Funct. Mater. 2025. https://doi.org/10.1002/adfm.202520907